Author: Sissy-Ve Basmer-Birkenfeld | Helmut Schmidt University

From 22 to 25 March 2023, an Open Source Machine Building Workshop was successfully held in Tunis to jointly develop Open Source Hardware. Funded by the German Federal Ministry of Education and Research, the Tunisian partners, led by Helmut Schmidt University, successfully built Open Source Machines for use in the local textile industry.

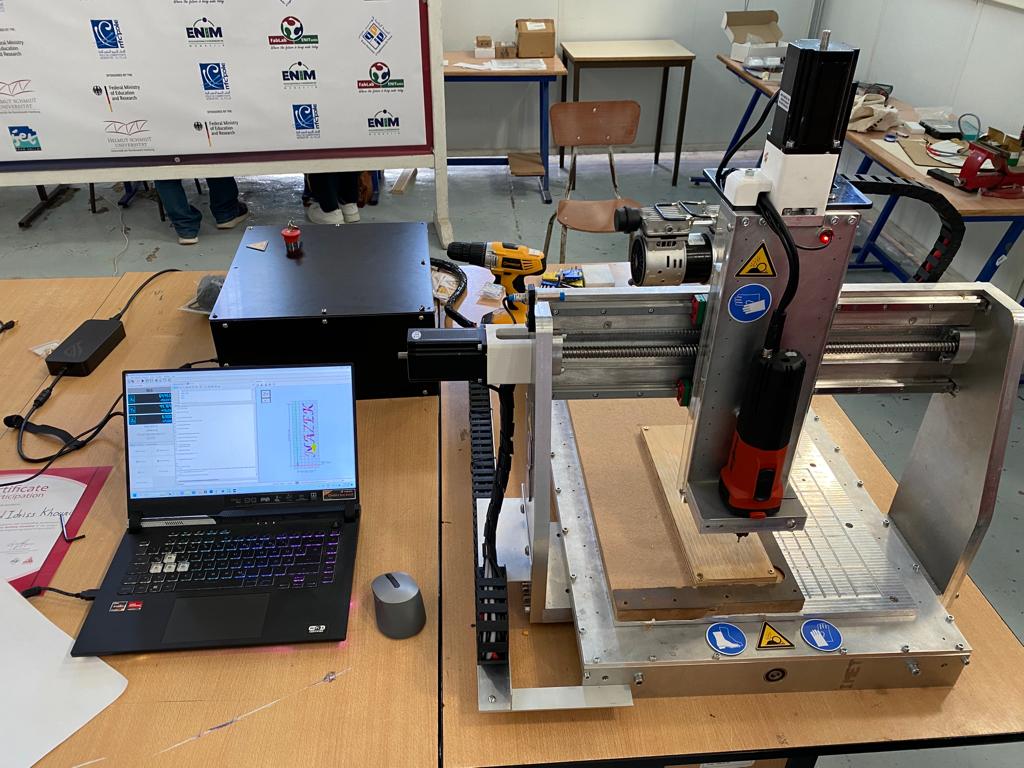

Milling machine developed during the workshop © ENIT

In only 4 days, from 22 to 25 March 2023, 50 participants built an Open Source laser cutter, an Open Source CNC milling machine and three Open Source 3D printers at the National Engineering School of Tunis (ENIT) - Tunis el Manar. The workshop was conducted as part of the German-Tunisian research project PISWI, funded by the German Federal Ministry of Education and Research. This project aims at closing gaps in technological learning, production, and innovation by implementing OpenLabs to test feasibility and develop policy recommendations for the Tunisian textile sector.

'As a project manager it is always very satisfying to see how the different partners and participants of the workshops come together with such motivation to learn and exchange ideas. The 4 days of the workshop were extremely busy, but also rewarding. We managed to finish building the 5 planned machines, which in itself is already a great success, but more than that, the participants expressed that they now feel more empowered to implement the learned knowledge to build and fix other machines,' expressed Project Manager Dr. Juan Manuel Grados Luyando.

The unequal socio-spatial distribution of value-added activities within global production networks leads to the limitation of high value-added activities such as machine design and manufacturing to specific locations in the world. As a result, a considerable number of people are excluded from related knowledge and know-how. The challenge is to tackle youth unemployment by empowering young Tunisians to utilise digital production technologies, to profit from international knowledge networks, and to create their own business models, thus enabling them to become entrepreneurs on their own terms.

By promoting bottom-up, grassroots technological and socio-economic development, the project is combining two key concepts: Open Fabrication Laboratories and Open Source Hardware. Thus, the concepts of digital production technologies, sharing and building knowledge in Open-Source networks can contribute to technological empowerment and socio-economic development.

This project is a follow-up of the first PISWI project, which was implemented in 2019. The research cooperation targets the potential of open production spaces for technological empowerment and innovation based on Open Source Appropriate Technology (OSAT). It proposes the development, implementation, and dissemination of OpenLabs as spaces for experiential technological learning, hardware product development and innovation using OSAT, thereby contributing to the development of an open manufacturing infrastructure in Tunisia. To achieve this, the research partners use a participatory action research approach that involves users and potential target groups in the development, implementation, and evaluation phases. In an in-depth exploratory single case study, it will be investigated how and under which conditions OSAT and open production spaces for technological empowerment and innovation in the field of digital manufacturing and product design can contribute to new ways of value creation.

The execution and implementation of the project are carried out in collaboration with local actors from research and industry in the Tunisian textile sector. The research network is coordinated by the Laboratory of Production Engineering/ New Production Institute of Helmut Schmidt University, while the local project management is conducted by the National Engineering School of Tunis (ENIT) - Tunis el Manar. The project implementation partners are the National Engineering School of Monastir (ENIM), the Higher Institute of Technology Studies Ksar Hellal (ISET) and the Monastir-El Fejja (la Manouba) competitiveness cluster (mfcpole).

Project duration: 1 April 2021 – 31 March 2024

Contact:

Dr.-Ing. Tobias Redlich

Helmut Schmidt University

Laboratory of Production Engineering/ New Production Institute

E-mail: tobias.redlich@hsu-hh.de

Dr. rer. nat. Juan Manuel Grados Luyando

Helmut Schmidt University

Laboratory of Production Engineering/ New Production Institute

E-mail: gradoslj@hsu-hh.de